cnc Hydraulic Bender / bending Machine

Basic Info

Model No.: as customer\'s requirment

Product Description

Specifications We can design different kinds of profile for downpipe machine.

Specifications 1. High Quality

2. easy to control

3. automatic driven

4. beautiful outlook Features

1. Hydraulic / Mechanical ram, synchronised positive stop design, ram stroke controlled by precision mechanical nut depth stops built into each cylinder. Electronically controlled by ENC-18 Programmable digital controller assuring accurate repeatability.Parallelism is ensured by torsion bar that can be easily adjusted by clutch system.

2. New style Digit type manual crowning conveniently mounted on the right side of the bed enabling operator to adjust simply by rotating the dial whilst the analogue digit system indicates the amount of movement

3. Segmented heavy duty 86° offset top punch is segmented for return bend clearance and incorporates a safety key to stop punch dropping.

4. Multi vee ('V') bottom die is made from solid die block design to handle heavy plate, safety edge vee ('V') is incorporated in bottom die block.

5. Conveniently mounted control box on pendant for quick swivel and adjustments.Enclosed rear gate with micro safety switches complete with sliding rear door for easy access.

6. Sliding steel fabricated sheet supports enabling a wide range of material sizes to be aligned and supported at the correct required height. This feature is achieved with a ‘T’ slot machined down the total length of the die bed; sheet supports are also adjustable vertically to assist in supporting material with return bends already folded.

7. Adjustable sliding blocks control the machines beam to provide desirable open height distance to the (slow speed) mute bending point. Operator adjustable locking knobs for quick adjustment, enables accurate repeatability and increased productivity.

8. Metal safety guarding surrounding the machine with rear sliding door fitted and micro switch ensuring operator safety. Clear access panels placed at each end of machine allows the operator to clearly view tooling and work piece during bending operation. Metal master specially design gates to suit safety requirements.

9. Hydraulic MPA pressure gauge mounted on right side of support frame with quick adjusting pressure control knob allowing operator to accurately set the pressure required for different material thickness, incorporating with hydraulic overload protection.

10. Welded steel fabricated synchronised torsion bar horizontally supporting main bending beam to provide consistent parallelism that also can be adjusted for taper correction. The vertical supporting slides are treated to provide greater ware resistance and increased accuracy.

11. Reinforced side frames providing addition support strength to machine throat

Machine Loading Because of the long trip and your super trust, we will make sure Purlin Roll Forming Machine can be appeared in front of you in fully good condition, you will fall in love with it with first glimpse!

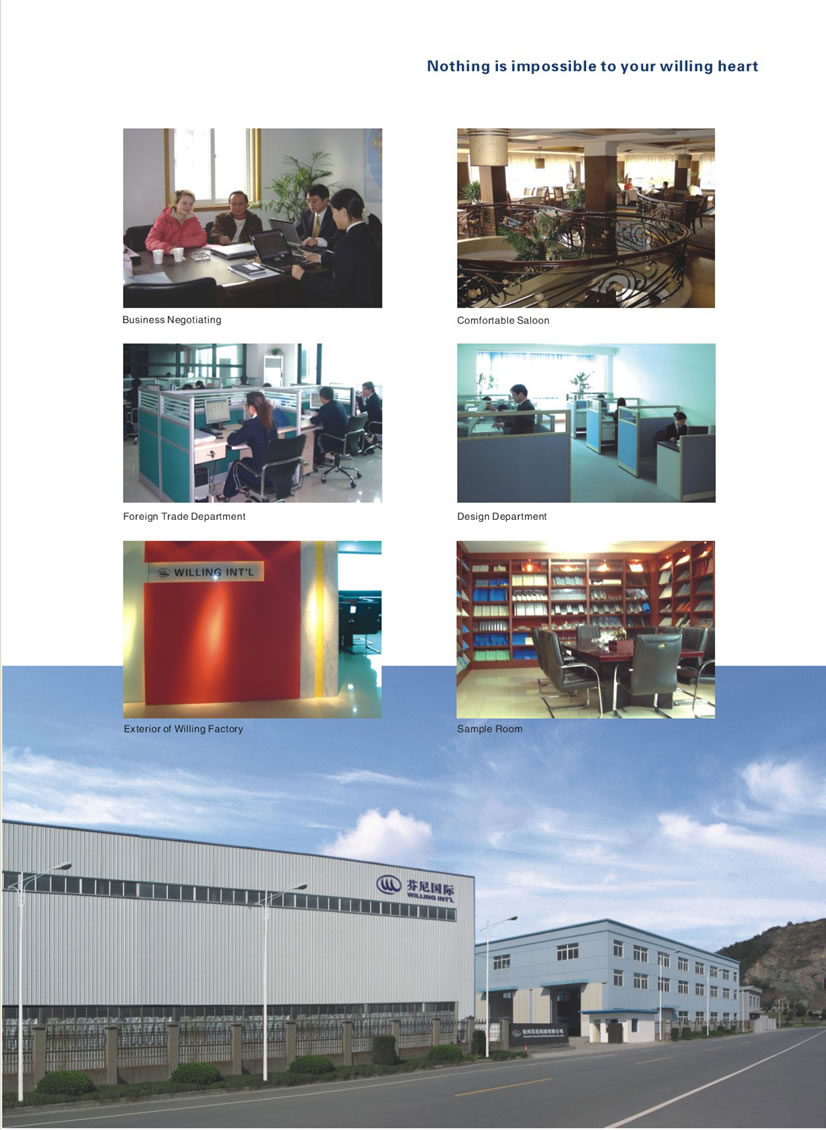

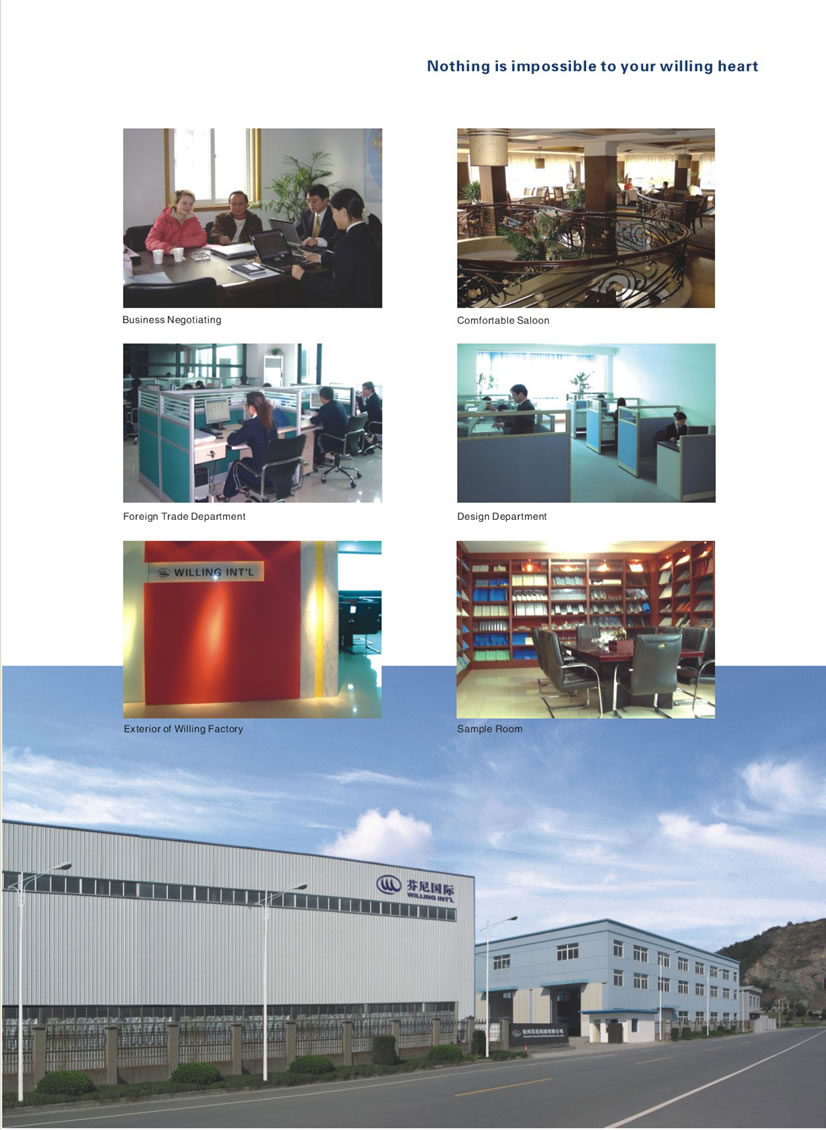

Machine Loading Because of the long trip and your super trust, we will make sure Purlin Roll Forming Machine can be appeared in front of you in fully good condition, you will fall in love with it with first glimpse!  5.We do our utmost, Why WILLING 1). Q: Do you have after sales support? A: Yes, we are happy to give advice and we also have skilled technicians available across the world. We need your machines running in order to keep your business running. 2). Q: How do your machines compare with other big companies in this market? A: We are up to date with the latest technology and improve our machines accordingly 3). Q: How does your factory do regarding quality control? A: Quality is priority. WILLING People always attach great importance to quality control from the very beginning to the end of the production. Every product will be fully assembled and carefully tested before it's packed for shipment. 4). Q: Do you sell only standard machines? A: No, most of our machines are built according to customers specifications, using top brand name components. 5). Q: Will you deliver the right goods as ordered? How can I trust you? A: Yes, we will. The core of our company culture is honesty and credit. If you check with WILLING, you will see that we have never got any complaint from our customers.

5.We do our utmost, Why WILLING 1). Q: Do you have after sales support? A: Yes, we are happy to give advice and we also have skilled technicians available across the world. We need your machines running in order to keep your business running. 2). Q: How do your machines compare with other big companies in this market? A: We are up to date with the latest technology and improve our machines accordingly 3). Q: How does your factory do regarding quality control? A: Quality is priority. WILLING People always attach great importance to quality control from the very beginning to the end of the production. Every product will be fully assembled and carefully tested before it's packed for shipment. 4). Q: Do you sell only standard machines? A: No, most of our machines are built according to customers specifications, using top brand name components. 5). Q: Will you deliver the right goods as ordered? How can I trust you? A: Yes, we will. The core of our company culture is honesty and credit. If you check with WILLING, you will see that we have never got any complaint from our customers.

The competitive advantage of product line: We mainly export to South America, Eastern Europe, Southeast Asia, Africa, Mid East, Central America and South Asia. They can be manufactured according to clients' requirements.

The competitive advantage of product line: We mainly export to South America, Eastern Europe, Southeast Asia, Africa, Mid East, Central America and South Asia. They can be manufactured according to clients' requirements.

Contact us if you need more details on Bender. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Cnc、Bending machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Bender. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Cnc、Bending machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Specifications 1. High Quality

2. easy to control

3. automatic driven

4. beautiful outlook Features

1. Hydraulic / Mechanical ram, synchronised positive stop design, ram stroke controlled by precision mechanical nut depth stops built into each cylinder. Electronically controlled by ENC-18 Programmable digital controller assuring accurate repeatability.Parallelism is ensured by torsion bar that can be easily adjusted by clutch system.

2. New style Digit type manual crowning conveniently mounted on the right side of the bed enabling operator to adjust simply by rotating the dial whilst the analogue digit system indicates the amount of movement

3. Segmented heavy duty 86° offset top punch is segmented for return bend clearance and incorporates a safety key to stop punch dropping.

4. Multi vee ('V') bottom die is made from solid die block design to handle heavy plate, safety edge vee ('V') is incorporated in bottom die block.

5. Conveniently mounted control box on pendant for quick swivel and adjustments.Enclosed rear gate with micro safety switches complete with sliding rear door for easy access.

6. Sliding steel fabricated sheet supports enabling a wide range of material sizes to be aligned and supported at the correct required height. This feature is achieved with a ‘T’ slot machined down the total length of the die bed; sheet supports are also adjustable vertically to assist in supporting material with return bends already folded.

7. Adjustable sliding blocks control the machines beam to provide desirable open height distance to the (slow speed) mute bending point. Operator adjustable locking knobs for quick adjustment, enables accurate repeatability and increased productivity.

8. Metal safety guarding surrounding the machine with rear sliding door fitted and micro switch ensuring operator safety. Clear access panels placed at each end of machine allows the operator to clearly view tooling and work piece during bending operation. Metal master specially design gates to suit safety requirements.

9. Hydraulic MPA pressure gauge mounted on right side of support frame with quick adjusting pressure control knob allowing operator to accurately set the pressure required for different material thickness, incorporating with hydraulic overload protection.

10. Welded steel fabricated synchronised torsion bar horizontally supporting main bending beam to provide consistent parallelism that also can be adjusted for taper correction. The vertical supporting slides are treated to provide greater ware resistance and increased accuracy.

11. Reinforced side frames providing addition support strength to machine throat

| No | Model | Nominal pressure | material length | Distance between column | Throat | Stroke | Back gauge | Motor | Dimension |

| (Ton) | (mm) | (mm) | (mm) | (mm) | (mm) | (kw) | (mm) | ||

| 1 | 40T/2500 | 40 | 2500 | 2050 | 200 | 110 | 600 | 4 | 2600x1270x1980 |

| 2 | 63T/2500 | 63 | 2500 | 2050 | 250 | 120 | 600 | 5.5 | 2600x1360x2050 |

| 3 | 100T/3200 | 100 | 3200 | 2500 | 320 | 150 | 600 | 7.5 | 3300x1400x2380 |

| 4 | 125T/3200 | 125 | 3200 | 2500 | 320 | 150 | 800 | 7.5 | 3300x1400x2380 |

| 5 | 160T/3200 | 160 | 3200 | 2500 | 320 | 200 | 800 | 11 | 3300x1550x2580 |

| 6 | 200T/3200 | 200 | 3200 | 2500 | 300 | 200 | 800 | 15 | 3300x1650x2930 |

| 7 | 200T/4000 | 200 | 4000 | 3100 | 300 | 200 | 800 | 15 | 4000x1650x3070 |

| 8 | 200T/6000 | 200 | 6000 | 4800 | 320 | 200 | 800 | 15 | 6200x1750x3360 |

Machine Loading Because of the long trip and your super trust, we will make sure Purlin Roll Forming Machine can be appeared in front of you in fully good condition, you will fall in love with it with first glimpse!

Machine Loading Because of the long trip and your super trust, we will make sure Purlin Roll Forming Machine can be appeared in front of you in fully good condition, you will fall in love with it with first glimpse!  5.We do our utmost, Why WILLING 1). Q: Do you have after sales support? A: Yes, we are happy to give advice and we also have skilled technicians available across the world. We need your machines running in order to keep your business running. 2). Q: How do your machines compare with other big companies in this market? A: We are up to date with the latest technology and improve our machines accordingly 3). Q: How does your factory do regarding quality control? A: Quality is priority. WILLING People always attach great importance to quality control from the very beginning to the end of the production. Every product will be fully assembled and carefully tested before it's packed for shipment. 4). Q: Do you sell only standard machines? A: No, most of our machines are built according to customers specifications, using top brand name components. 5). Q: Will you deliver the right goods as ordered? How can I trust you? A: Yes, we will. The core of our company culture is honesty and credit. If you check with WILLING, you will see that we have never got any complaint from our customers.

5.We do our utmost, Why WILLING 1). Q: Do you have after sales support? A: Yes, we are happy to give advice and we also have skilled technicians available across the world. We need your machines running in order to keep your business running. 2). Q: How do your machines compare with other big companies in this market? A: We are up to date with the latest technology and improve our machines accordingly 3). Q: How does your factory do regarding quality control? A: Quality is priority. WILLING People always attach great importance to quality control from the very beginning to the end of the production. Every product will be fully assembled and carefully tested before it's packed for shipment. 4). Q: Do you sell only standard machines? A: No, most of our machines are built according to customers specifications, using top brand name components. 5). Q: Will you deliver the right goods as ordered? How can I trust you? A: Yes, we will. The core of our company culture is honesty and credit. If you check with WILLING, you will see that we have never got any complaint from our customers.

The competitive advantage of product line: We mainly export to South America, Eastern Europe, Southeast Asia, Africa, Mid East, Central America and South Asia. They can be manufactured according to clients' requirements.

The competitive advantage of product line: We mainly export to South America, Eastern Europe, Southeast Asia, Africa, Mid East, Central America and South Asia. They can be manufactured according to clients' requirements.

Contact us if you need more details on Bender. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Cnc、Bending machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Bender. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Cnc、Bending machine. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Wall And Roof Roll Forming Machine

Premium Related Products

Other Products

Hot Products

Color Steel Roofing Tile / Color/Galvanized corrugated roofing sheet/Metal tile sheetsquare water pipe machineHighway Guardrail Forming Machine,Highway Guardrail Roll Forming MachinePolyurethane Sandwich PanelEPS Sandwich PanelZ Purlin MachineDecking PanelEPS Foamed Plastic MachineRoll Forming MachineRoll Forming Machine,Forming Machine,Roll formerSteel Embossing MachineSteel StructureCut to Length LineShearing MachineHydraulic Uncoiler MachineForming Machine